01

Bonded PC Strand

Product Description

1.Introductions: Since 2005 the production of stabilized reinforcement strands/pc strands with low relaxation has been developed. In 2016, the enterprise put into operation new up-to-date equipment that allows to produce stabilized reinforcement strands up to 300,000 tons per year.

The most up-to-date technologies which meet the buyer's requirements at the existing system of

quality control are used at the strands' production.

2.Applications: PC strands/Reinforcement stabilized strands are produced with wide range of application at the production of large constructions: buildings, structures, bridges, conduits, reservoirs, airports, tunnels hangars,oil-drilling platforms, nuclear power stations; at the production of concrete railway sleepers.

3.Advantageous:PC strands/Reinforcement stabilized strands have the excellent performance of high low relaxation and ductility ,which have a wide range of application in the construction of complex and responsible trade and industrial facilities.

1)The application of multi-wire reinforcement stabilized strands allows to achieve the same strength in prestressed constructions without increasing the diameter and the number of strands with obvious economy on account of their fastening at the anchors.

2)The good mechanical characteristics of reinforcement strands after heat and mechanical treatment continuous improvement of the technology have a decisive significance in the use of steel products in the building industry and make reinforcement strands for prestressed concrete constructions by one of the main products.

4.Characteristics: The use of multi-strand reinforcing strands instead of rolling reinforcement allows to obtain high strength characteristics with smaller diameters and weight of the reinforcing structure. The flexibility of the strands greatly facilitates the design and construction of complex structures.

5.Standards : PC strands/Reinforced stabilized strands are made in accordance with the requirements of the following standards:

1)PC strands according to FprEN 10138-3: 2009 “Tensile reinforcement – Part 3: Strand” – according to the design 3- and 7-strands from wire of round or periodic cross-section;

2)PC strands according to BS 5896: 2012 “Steel wire with high temporary tensile strength and strands from it to create prestress in concrete Strands”;

3)PC strands according to ASTM A 416 / A416M-18 “Standard specifications for 7-wire steel strands without coating for prestressed concrete”. From a wire of only round section;

4)PC strands (reinforcing ropes) according to GOST 13840-68 “Steel reinforcing ropes 1×7. Technical conditions”;

5)PC strands (reinforcing ropes) according to GOST R 53772-2010 “7-wire stabilized reinforcing steel ropes. Technical conditions.”;

6)PC reinforcement stabilized strands (ropes) according to SFS – 1265 – 3:2014“Prestressing steels prestressed constructions – Part 3: Strand”

6. PC Strands according to national technical assessments based on EN 10138, parts 1 and 3:

1) Romanian technical regulation ST 009-2011 “Technical specifications for steel products used as reinforcement: operational requirements and criteria” and Technical agreement 001SC-01 / 275-2019 “Reinforcing strand for prestressed concrete”

2) Polish national technical assessment ITB-KOT-2018/0637 issue 1 “Steel prestressed strands of PJSC “STALKANAT-SILUR” from smooth wires ”;

3) Hungarian National Technical Assessment NMÉ: A-16/2018 and NMÉ: A-27/2019;

DIAMETER: from 6,50 mm up to 17,8 mm.

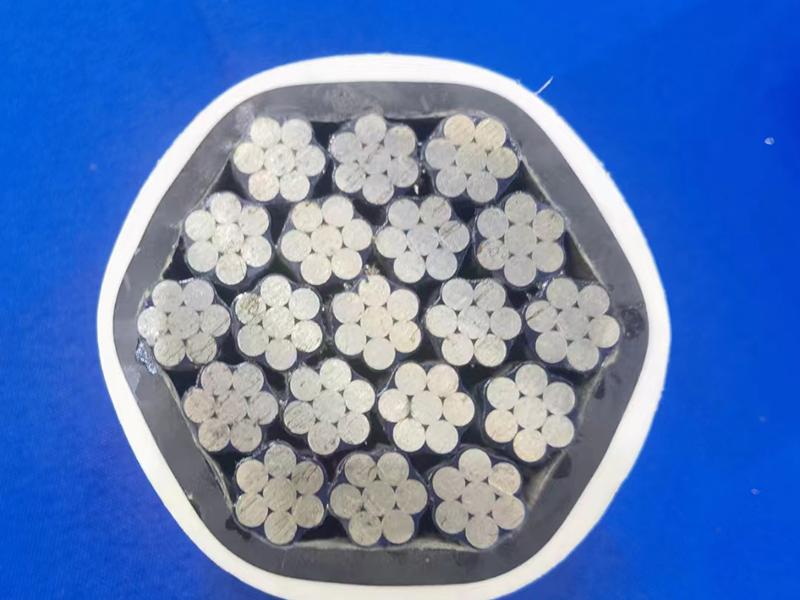

STRUCTURE: 3-strands wire and 7-strands wire coating or without coating.

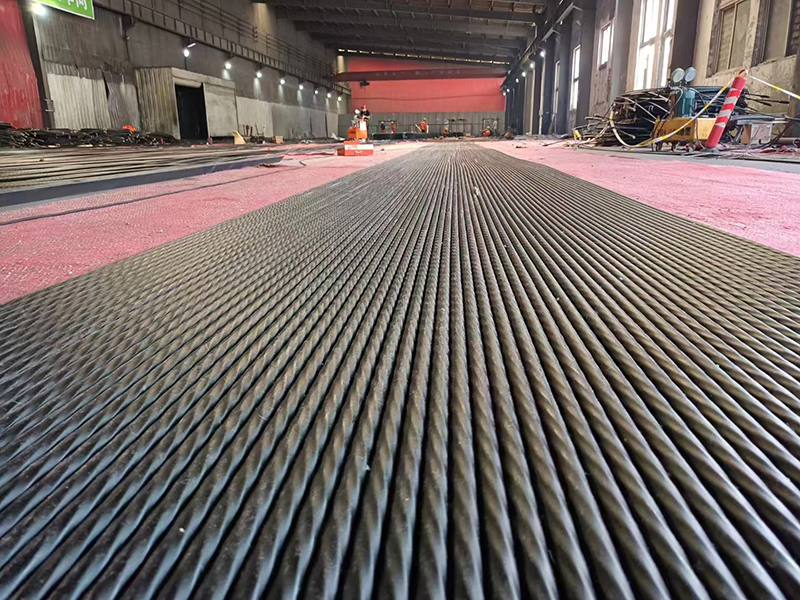

RAW MATERIAL: cold-drawn wire, made of high carbon wire rod of diameter 6,5 ~ 13,0 mm is used for the reinforcement strands production.

Chemical Composition Of High Carbon Wire Rod

|

С, % |

Mn, % |

Si, % |

S, % |

P, % |

Cr, % |

|

0,77~0,90 |

0,40~0,70 |

0,17~0,37 |

≤0,035 |

≤ 0,035 |

0,15~0,25 |

New modern production equipment, a testing laboratory equipped for testing of standard and special properties, experienced specialists guarantee the satisfaction of any requests and expectations of the customers.

At the request of the customer, the strands can be made from indented wire, while the central wire in the strand is made smooth. 7-wire/3-wire strands can be made from smooth wire and from indented wire.