Difference Between Seamless And Welded Pipe: Which is Best?

Univac New Materials Tech Manufacturing Co., Ltd. is proud to introduce our high-quality seamless and welded pipes. Our seamless pipes are manufactured through a process that involves the piercing of a solid steel billet to produce a hollow pipe, resulting in a product with exceptional strength and durability. On the other hand, our welded pipes are created by welding a flat strip of steel into a tubular shape, providing a cost-effective and reliable solution for various applications, The main difference between seamless and welded pipes lies in their manufacturing processes. Seamless pipes are known for their uniform structure and strength, making them suitable for high-pressure applications and critical industrial environments. Welded pipes, on the other hand, offer good dimensional accuracy and can be produced in larger sizes, making them suitable for a wide range of commercial and industrial uses, At Univac New Materials Tech Manufacturing Co., Ltd., we are committed to providing our customers with superior quality pipes that meet their specific requirements. Whether you need seamless or welded pipes, you can trust us to deliver products that exceed industry standards and expectations. Contact us today to learn more about our seamless and welded pipes and how they can benefit your project

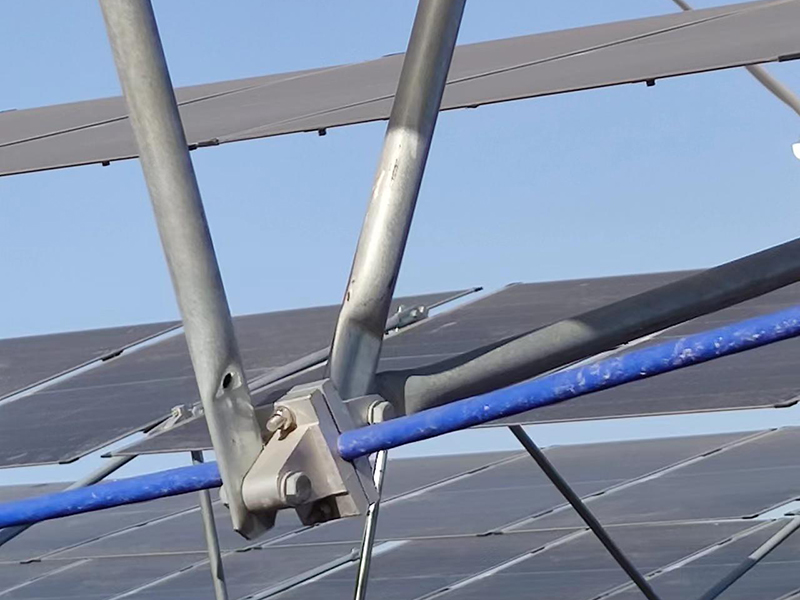

- OEM Galvanized Carbon Steel Pipe Suppliers

- Cheap Pipe Manufacturing Process Manufacturer

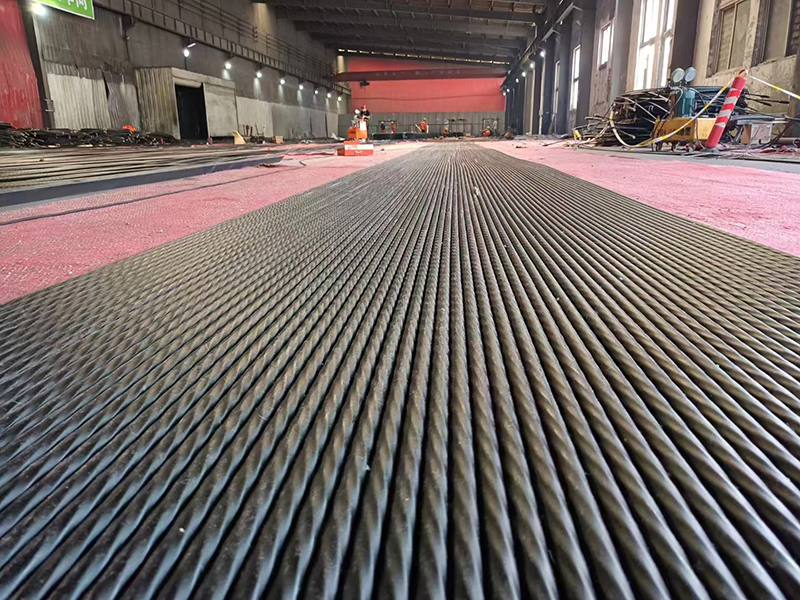

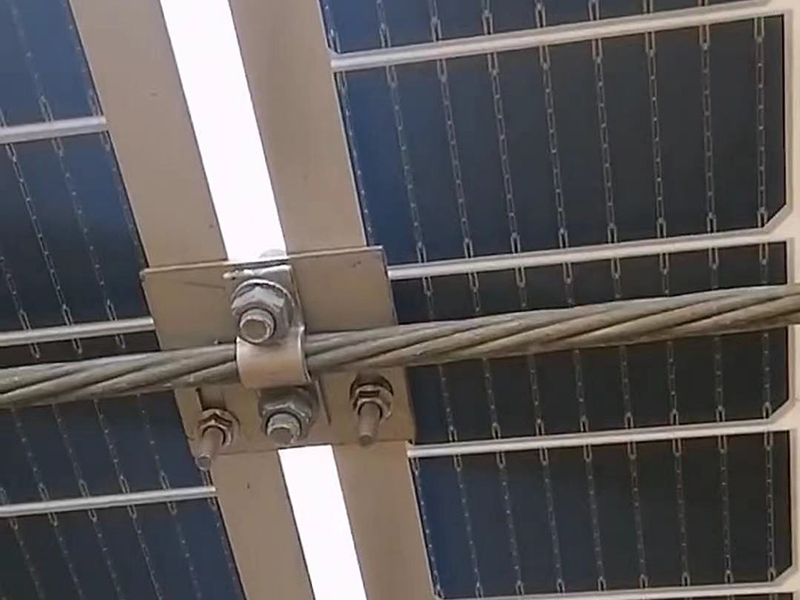

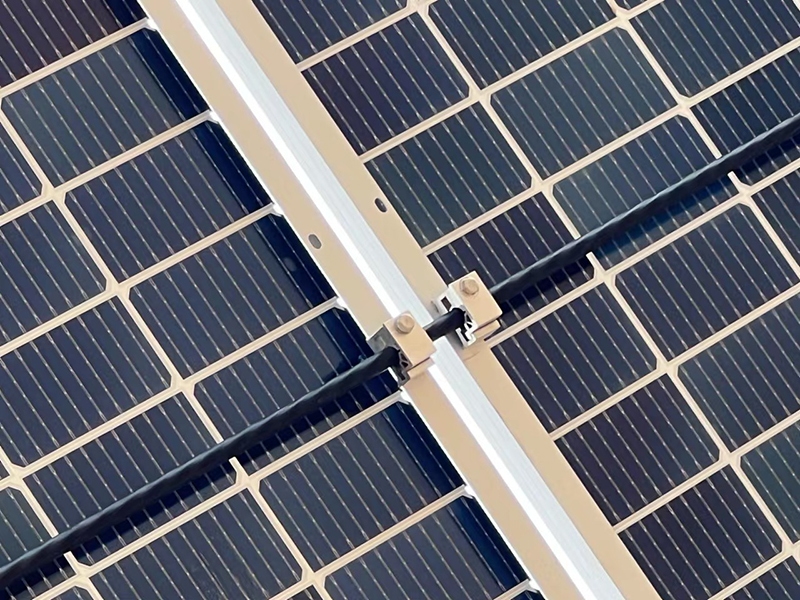

- ODM Low Relaxation Prestressed Concrete Strand Products

- China Standard Scaffolding Pipe Size Manufacturer

- Wholesale A106b Material Properties Supplier

- OEM Reinforcement Test

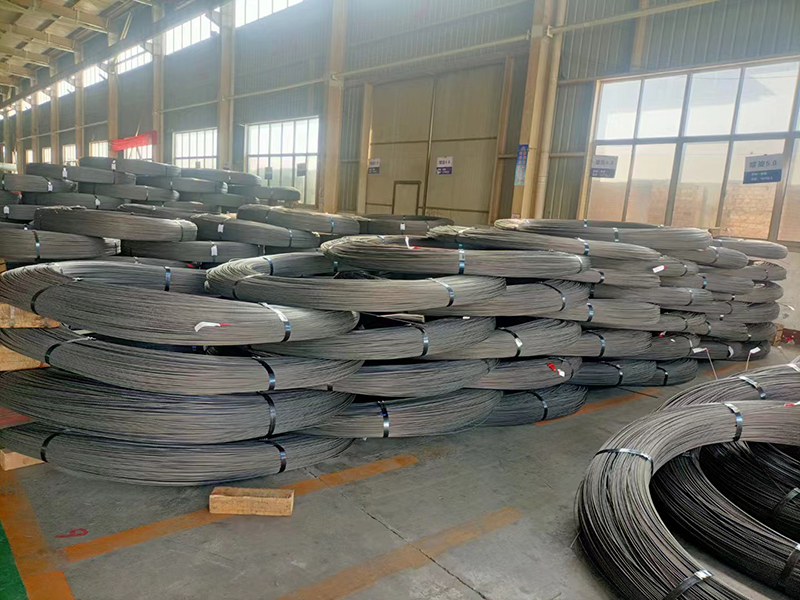

- Wholesale Prestressed Concrete Cables

- Cheap Tie Rod Construction

- Wholesale A106 Material Properties Supplier

- OEM Api 5l Chemical Composition