01

Piping Pipes

Khoom Taw Qhia

Cov qauv siv:

Piping kav feem ntau yog cais raws li cov khoom uas lawv tau ua los ntawm, uas muaj peev xwm muaj xws li carbon steel, alloy steel, los yog lwm yam ntaub ntawv. Cov txheej txheem tshwj xeeb ntawm cov khoom siv yuav yog nyob ntawm daim ntawv thov npaj thiab ib puag ncig uas yuav siv cov yeeb nkab piling.

Manufacturing Standards:

Kev tsim cov txheej txheem ntawm piling yeeb nkab yuav tsum tau ua raws li cov qauv tshwj xeeb los xyuas kom meej qhov zoo, kev ntseeg tau thiab kev ua tau zoo ntawm cov yeeb nkab. Cov qauv no yuav raug tsim los ntawm cov koom haum xws li American Society for Testing and Materials (ASTM), American Petroleum Institute (API), lossis lwm lub koom haum hauv teb chaws lossis thoob ntiaj teb cov qauv.

Cov qauv tsim:

Piping kav tej zaum yuav tsum tau ua kom tau raws li cov qauv tsim los xyuas kom meej lawv cov qauv kev ncaj ncees thiab lub peev xwm thauj khoom. Cov qauv no tuaj yeem tsim los ntawm engineering thiab kev tsim kho cov koom haum lossis tsoomfwv cov koomhaum tswj hwm.

Cov qauv tsim khoom:

Cov txheej txheem tsim khoom ntawm Submerged-Arc Welded Steel Pipes tuaj yeem ua raws li cov qauv tshwj xeeb uas tau teev tseg los ntawm cov koom haum xws li American Petroleum Institute (API), American Society for Testing and Materials (ASTM), lossis lwm lub koom haum hauv teb chaws lossis thoob ntiaj teb cov qauv raws li hauv qab no: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458, IS 3589, GB / T3091, GB / T9711, EN10217, EN10219

Daim Ntawv Thov:

Cov kav dej tuaj yeem raug cais raws li lawv qhov kev npaj siv, xws li kev sib txuas hauv hiav txwv, cov hauv paus piling, lossis cov hom av lossis geological tej yam kev mob. Nws yog ib qho tseem ceeb uas yuav tau sab laj txog cov qauv tshwj xeeb thiab cov kev faib tawm uas cuam tshuam nrog hom piling yeeb nkab uas yuav tsum tau ua rau ib qhov project. Yog tias koj muaj cov txheej txheem tshwj xeeb lossis kev faib tawm, thov koj xav tias dawb muab cov ntsiab lus ntxiv kom kuv tuaj yeem muab cov ntsiab lus ntxiv.

Txheej txheem:

SSAW - Kauv Submerged arc welded

LSAW – UO(UOE), RB(RBE), JCO(JCOE)

DSAW - Ob chav Submerged arc welded

Qhov Loj:

Tawm Dav: 355.6mm-1626mm

Phab ntsa Thickness: 8-50mm

Ntev: mus txog 12m

Steel Qib:

API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

Nto: Fusion daim ntawv cog lus Epoxy txheej, Coal Tar Epoxy, 3PE, Vanish Txheej, Bitumen txheej, Dub Roj txheej raws li tus neeg siv khoom xav tau

Test: Chemical Component Analysis, Mechanical Properties (Qhov kawg tensile zog, Yield zog, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), External Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204 / 3.1B

Daim Ntawv Thov Cov Txheej Txheem: Cov kav dej ntev ntev kuj tuaj yeem raug cais raws li nws cov kev xav tau siv, xws li cov kav dej thiab roj, kev siv cov qauv, lossis kev siv dav dav. Nco ntsoov xa mus rau cov qauv tshwj xeeb thiab kev faib tawm uas cuam tshuam rau koj cov kev xav tau tshwj xeeb, vim lawv yuav txawv raws li kev lag luam thiab cheeb tsam.

API 5L Kab Yeeb

API 5L PSL1/PSL2 GR B, X42, X46, X52, X60, X65, X70

MECHANICAL PROPERTIES THIAB STEEL CHEMICAL COMPOSITION

| STEEL Qib | Yield zog, min. psi (MPa) | Tensile zog, min. psi (MPa) | Elongation hauv 2 hauv., min. % |

| GR B | 245 | 415 |  |

| X42 | 290 | 415 | |

| X46 | 320 | 4 35 | |

| X52 | 360 | 460 | |

| X56 | 390 | 490 ib | |

| X 60 | 415 | 520 | |

| X 65 | 450 | 535 ib | |

| X 70 | 485 ib | 570 ib |

| STEEL Qib | % los ntawm huab hwm coj, Maximum | ||||

| C | Thiab | Mn | P | S | |

| GR B | 0.26 | 0.40 ib | 1.20 | 0.030 Nws | 0.030 Nws |

| X42 | 0.26 | 0.40 ib | 1.30 Nws | 0.030 Nws | 0.030 Nws |

| X46 | 0.26 | 0.40 ib | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X52 | 0.26 | 0.40 ib | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X56 | 0.26 | 0.40 ib | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X 60 | 0.26 | 0.40 ib | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X 65 | 0.26 | 0.40 ib | 1.45 Nws | 0.030 Nws | 0.030 Nws |

| X 70 | 0.26 | 0.40 ib | 1.65 ib | 0.030 Nws | 0.030 Nws |

ASTM A53 GR. B

MECHANICAL PROPERTIES THIAB STEEL CHEMICAL COMPOSITION

| STEEL Qib | Kev sib xyaw ua ke Max,% | ||||||||

| C | Mn | P | S | Nrog | Hauv | Cr | Mo | IN | |

| GR B | 0.30 Nws | 1.20 | 0.05 Nws | 0.05 Nws | 0.40 ib | 0.40 ib | 0.40 ib | 0.15 | 0.08 ib |

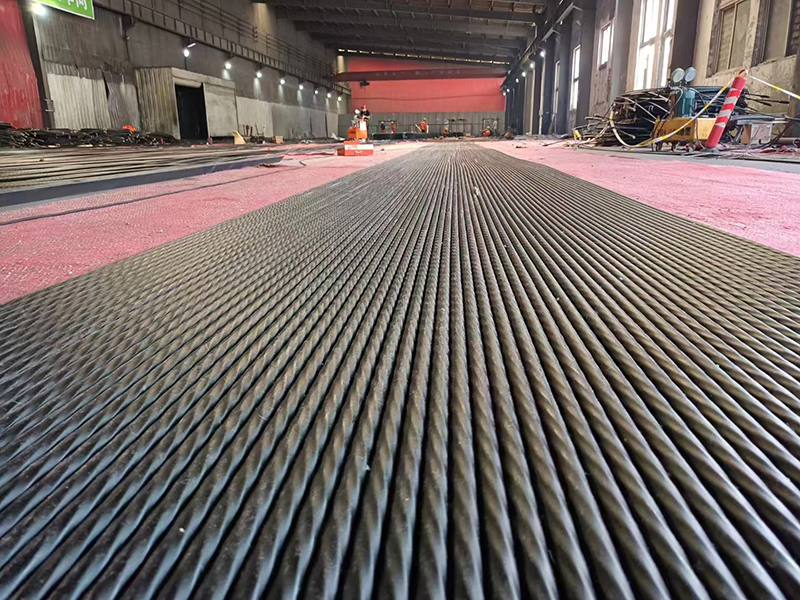

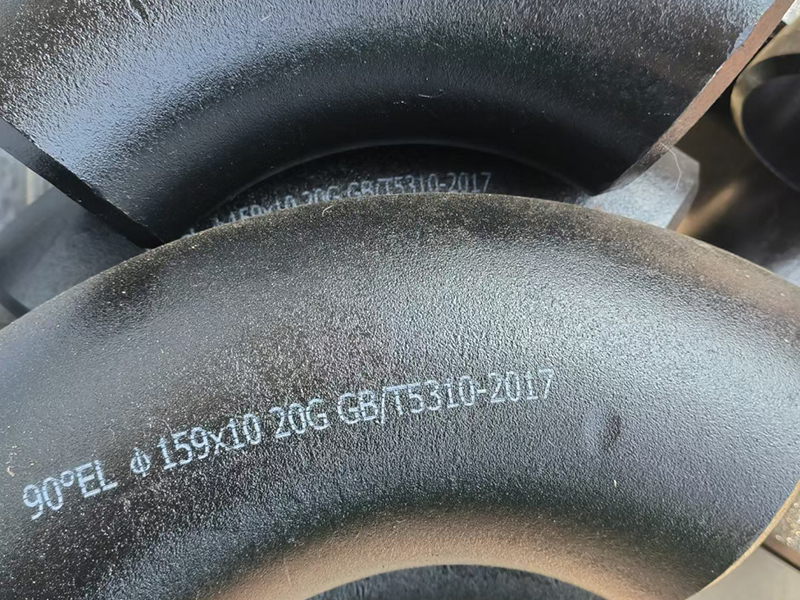

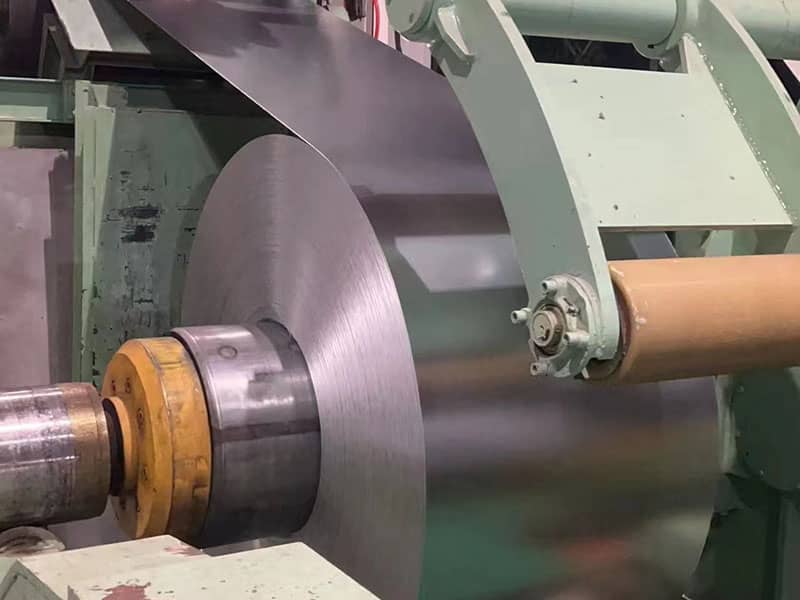

Kev cob qhia thiab cov cuab yeej tsim khoom

0102 ib0304 ib050607 ib0809 ib