01

Cov kav dej nrog Txheej rau Anti-corrossion

Khoom Taw Qhia

Qauv: Cov qauv rau kev tiv thaiv corrosion coated kav yog tsim los ntawm cov koom haum xws li American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO) thiab National Society of Corrosion Engineers (NACE). Cov qauv no qhia txog cov kev xav tau ntawm cov ntaub ntawv txheej, cov txheej txheem kev thov, cov txheej txheem xeem thiab cov qauv kev ua haujlwm.

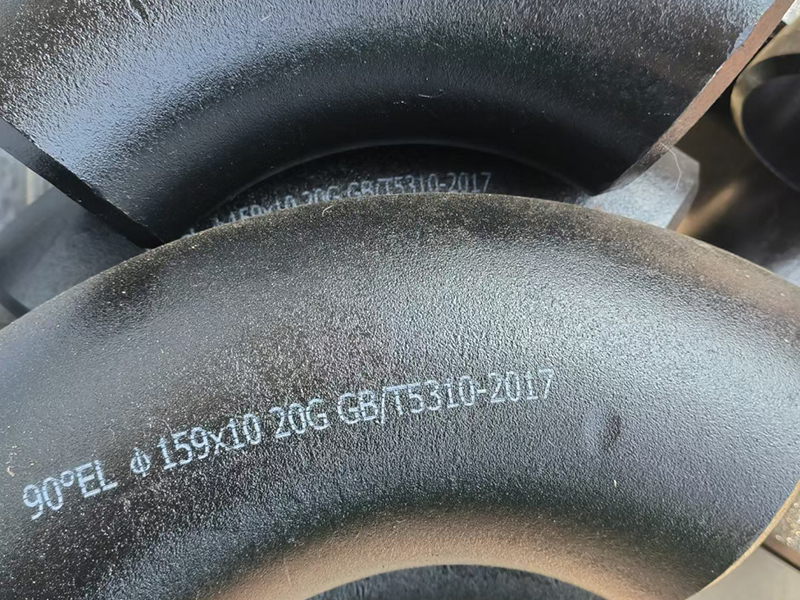

Kev faib tawm raws li kev kho saum npoo: Cov kav dej uas muaj cov tshuaj tiv thaiv corrosion tuaj yeem raug cais raws li hom txheej siv. Cov pawg muaj xws li: Fused Bonded Epoxy (FBE) Txheej Polyethylene (PE) lossis polypropylene (PP) txheej Asphalt lossis asphalt txheej Zinc nplua nuj xim Polyurethane txheej Coal tar enamel txheej.

Daim ntawv thov: Cov kav dej uas muaj cov tshuaj tiv thaiv corrosion yog dav siv nyob rau hauv ntau yam lag luam, xws li: Roj thiab Roj: Cov kav dej siv los thauj cov roj av, roj av thiab cov khoom siv roj av, dej thiab dej khib nyiab: rau cov dej hauv av thiab cov kav dej phwj tshuaj thiab petrochemical: thauj cov tshuaj corrosive thiab acids Marine. thiab offshore: rau subsea pipelines thiab offshore structures Infrastructure: Siv rau cov choj, docks thiab lwm yam qauv raug rau hnyav ib puag ncig tej yam kev mob Cov kav dej no yog ib qho tseem ceeb rau kev tswj kom muaj kev ncaj ncees thiab ntev ntev ntawm cov infrastructure thiab industrial systems, tshwj xeeb tshaj yog nyob rau hauv hnyav los yog corrosive ib puag ncig. Thaum qhia lossis xaiv cov yeeb nkab nrog cov txheej tiv thaiv corrosion, nws yog ib qho tseem ceeb uas yuav tsum tau xa mus rau cov qauv tsim nyog thiab sab laj nrog cov kws tshaj lij kev lag luam kom ntseeg tau tias cov txheej txheem xaiv tau raws li cov kev cai tshwj xeeb ntawm daim ntawv thov.

Steel Qib:

API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

Test: Chemical Component Analysis, Mechanical Properties (Qhov kawg tensile zog, Yield zog, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), External Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

API 5L Kab Yeeb

API 5L PSL1/PSL2 GR B, X42, X46, X52, X60, X65, X70

MECHANICAL PROPERTIES THIAB STEEL CHEMICAL COMPOSITION

| STEEL Qib | Yield zog, min. psi (MPa) | Tensile zog, min. psi (MPa) | Elongation hauv 2 hauv., min. % |

| GR IB | 245 | 415 |  |

| X42 | 290 | 415 | |

| X46 | 320 | 4 35 | |

| X52 | 360 | 460 | |

| X56 | 390 | 490 ib | |

| X 60 | 415 | 520 | |

| X 65 | 450 | 535 ib | |

| X 70 | 485 ib | 570 ib |

| STEEL Qib | % los ntawm huab hwm coj, Maximum | ||||

| C | Thiab | Mn | P | S | |

| GR IB | 0.26 | 0.40 Nws | 1.20 | 0.030 Nws | 0.030 Nws |

| X42 | 0.26 | 0.40 Nws | 1.30 Nws | 0.030 Nws | 0.030 Nws |

| X46 | 0.26 | 0.40 Nws | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X52 | 0.26 | 0.40 Nws | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X56 | 0.26 | 0.40 Nws | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X 60 | 0.26 | 0.40 Nws | 1.40 Nws | 0.030 Nws | 0.030 Nws |

| X 65 | 0.26 | 0.40 Nws | 1.45 Nws | 0.030 Nws | 0.030 Nws |

| X 70 | 0.26 | 0.40 Nws | 1.65 ib | 0.030 Nws | 0.030 Nws |

ASTM A53 GR. B

MECHANICAL PROPERTIES THIAB STEEL CHEMICAL COMPOSITION

| STEEL Qib | Kev sib xyaw ua ke Max,% | ||||||||

| C | Mn | P | S | Nrog | Hauv | Cr | Mo | IN | |

| GR IB | 0.30 Nws | 1.20 | 0.05 Nws | 0.05 Nws | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

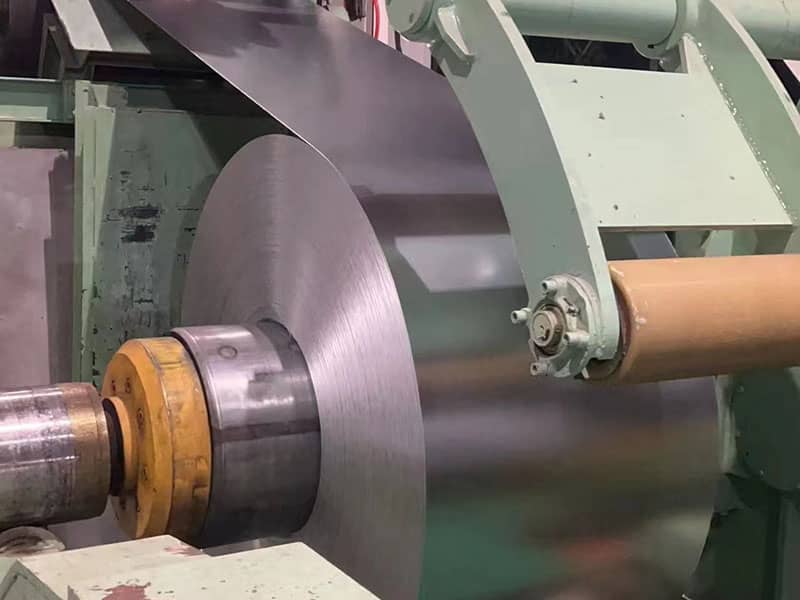

Kev cob qhia thiab cov cuab yeej tsim khoom

0102 ib0304 ib050607 ib0809