0102030405

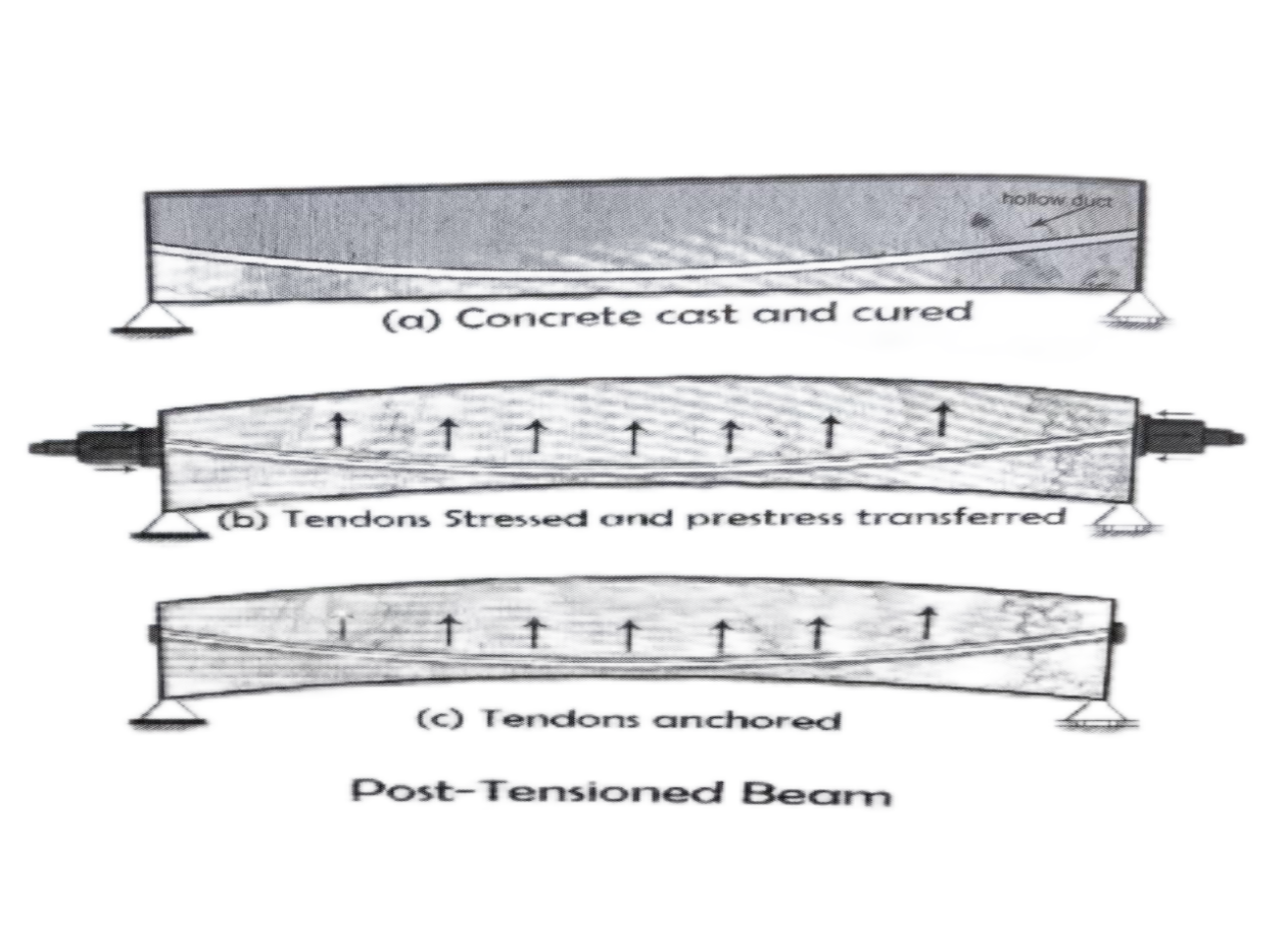

Procedures for prestressed tensioning and construction

2024-09-07 16:10:31

Prestressed tensioning must comply with relevant applications technical regulations and be carried out in strict accordance with the pre-programmed tensioning operating procedures.

■For cutting of prestressed tendons, a grinding wheel saw should be used and arc cutting is not allowed;

■When braiding steel strands, they should be straightened out one by one and bundled into bundles without disorder. The extruded anchor or embossed anchor at the fixed end of the steel strand should be assembled with the pressure-bearing plate and spiral reinforcement in advance.

■The machines, equipment and instruments used to apply prestressing force should be regularly maintained and calibrated;

■Before the prestressing tendons are stretched, a concrete strength test report should be provided. Prestress can only be applied when the cubic strength of the concrete meets the design requirements and is no less than the specified lining strength of the concrete in the anchorage area during tension construction.

■Before tensioning the prestressed tendons, the surface of the pressure-bearing plate should be cleaned and the quality of the concrete behind the pressure-bearing plate should be checked. If there is a hollow phenomenon in the concrete, it should be repaired before tensioning.

■When installing the anchor, the anchor plate should be aligned, the clips should be tightened, and the clips should be evenly spaced: However, when tightening the clips, do not hit it too hard to avoid damaging the clips:

■Before the large-tonnage prestressed tendons are officially tensioned, they should be Work with professionals to conduct test tensioning. Only after confirming that the tensioning process is reasonable, the tensile elongation value is normal, and no harmful cracks appear, can the tensioning be carried out in batches. Determine the actual channel friction loss if necessary.

■When tensioning the prestressed tendons, they should first be loaded from zero to the initial tension at which the elongation value is measured, and then loaded in stages to the required tension;

■Tension management of prestressed tendons, adopting stress control and elongation check. The allowable deviation between the actual elongation value and the calculated elongation value is -5%~+10%. If the value is exceeded, the tensioning should be suspended; measures can be taken to adjust before the tensioning can be continued; if the elongation value is too small, super-tensioning measures can be taken, but the tension limit should not be greater than the 0.8fptk value; in the multi-wave curve In prestressed tendons, in order to increase the tensile stress at the inner bearing and reduce the tensile stress at the lower end of the anchor after tensioning, over-tensioning and loosening technology can be adopted;

■The grouting in the tunnel should be dense, and the cement slurry strength grade should not be lower than C30. Before grouting, the tunnel should be moist and clean. Grouting should be carried out slowly and evenly without interruption and the exhaust should be smooth. If the hole is blocked, the grouting port must be replaced, but the cement slurry poured for the first time must be discharged to avoid the presence of bodies between the cement poured twice. After filling the pores and sealing the pores, it is advisable to continue to pressurize to 0.5~0.6MPa, and then seal the grouting holes later. The grouting pressure of vertical holes is determined based on the grout height;

■When grouting the channels of multi-span continuous prestressed tendons connected by connectors, one span should be grouted after one span has been stretched, and grouting must not be done all at once after all spans have been stretched; when installing a P anchor extrusion head on the circumference of the connector , pay attention to the extrusion head must be installed in place, and can be tied and fixed with thin iron wire.

■The exposed length of the prestressed steel bars after anchoring is 20mm~50mm, and the anchors should be protected by end-capping concrete. When it needs to be exposed for a long time, measures to prevent corrosion should be taken; when there is floating rust on the steel strand, please clean the floating rust and dirt on the steel strand at the outer end of the anchor clamping section to avoid floating rust during installation and tensioning. , Dirt fills the teeth of the clip and causes slippage.

■The tool clip is a three-piece type and the work clip is a two-piece type. The two cannot be mixed; the working anchor cannot be reused. Anchors must be properly kept and must not be rusty, water-contaminated or contaminated with other debris during use, and must not be conducted by current. The working clip can be used without the wrapping paper. When the prestressed beam is long and must be repeatedly tensioned and anchored, it is recommended to apply a small amount of lubricant (such as anchor withdrawal spirit) in the tapered hole of the anchor plate, which is beneficial to the tracking of the working clip. It is called anchor withdrawal and is conducive to multiple anchorings of the anchor. Apply lubricant on the outer surface of the tool clip and the inner surface of the anchor plate taper hole before use, and frequently clean the surface of the clip to make the anchor withdrawal flexible. However, when When the clip is cracked or the tooth surface is damaged, it needs to be replaced and must not be used again;

■Safety measures should be taken when tensioning. No one should stand within 60m of the backward radiation of the tensioning jack;

■The anchor system should be used in conjunction with other systems and cannot be mixed with other systems. If you do a static load test, please wipe the anti-rust oil on the clips and anchor plate holes with gauze, otherwise it will affect the anchoring performance.