01

Pipes with Coatings for Anti-corrossion

Products Introduction

Standards: Standards for anti-corrosion coated pipes are set by organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO) and the National Society of Corrosion Engineers (NACE). These standards specify requirements for coating materials, application methods, test procedures and performance standards.

Classifications based on surface treating: Pipes with anti-corrosion coatings can be classified based on the type of coating used. Common categories include:Fused Bonded Epoxy (FBE) Coating Polyethylene (PE) or polypropylene (PP) coating Asphalt or asphalt coating Zinc rich paint Polyurethane coating Coal tar enamel coating.

Applications: Pipes with anti-corrosion coatings are widely used in various industries, including:Oil and Gas: Pipelines used to transport crude oil, natural gas and petroleum products Water and wastewater: for groundwater and sewerage Chemical and petrochemical: for transporting corrosive chemicals and acids Marine and offshore: for subsea pipelines and offshore structures Infrastructure: For use on bridges, docks and other structures exposed to harsh environmental conditions These pipes are critical to maintaining the integrity and longevity of critical infrastructure and industrial systems, especially in harsh or corrosive environments. When specifying or selecting pipe with an anti-corrosion coating, it is important to refer to relevant standards and consult with industry experts to ensure that the chosen coating meets the specific requirements of the intended application.

Steel Grade:

API 5L: GR B, X42,X46, X56, X60,X65,X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

API 5L Line Pipe

API 5L PSL1/PSL2 GR B , X42, X46, X52, X60, X65, X70

MECHANICAL PROPERTIES AND STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

|

GR B |

245 |

415 |

|

|

X42 |

290 |

415 |

|

|

X46 |

320 |

435 |

|

|

X52 |

360 |

460 |

|

|

X56 |

390 |

490 |

|

|

X60 |

415 |

520 |

|

|

X65 |

450 |

535 |

|

|

X70 |

485 |

570 |

|

STEEL GRADE |

% by mass, Maximum |

||||

|

C |

Si |

Mn |

P |

S |

|

|

GR B |

0.26 |

0.40 |

1.20 |

0.030 |

0.030 |

|

X42 |

0.26 |

0.40 |

1.30 |

0.030 |

0.030 |

|

X46 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X52 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X56 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X60 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X65 |

0.26 |

0.40 |

1.45 |

0.030 |

0.030 |

|

X70 |

0.26 |

0.40 |

1.65 |

0.030 |

0.030 |

STEEL PIPES AS PER ASTM A53 GR. B

MECHANICAL PROPERTIES AND STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

Composition Max, % |

||||||||

|

C |

Mn |

P |

S |

Cu |

Ni |

Cr |

Mo |

V |

|

| GR B |

0.30 |

1.20 |

0.05 |

0.05 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

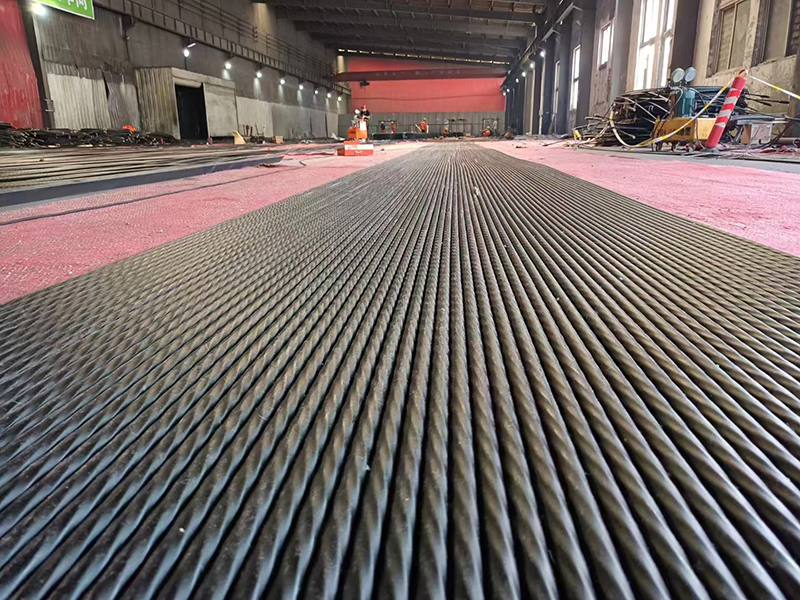

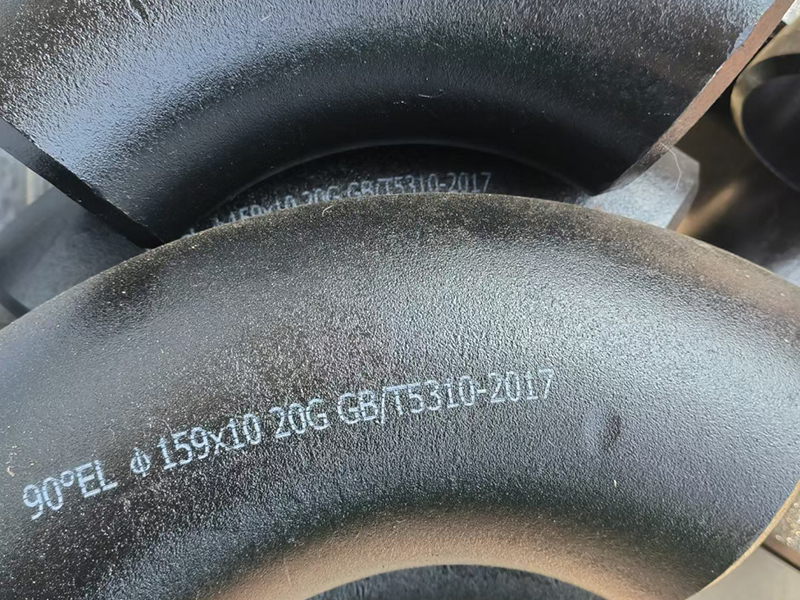

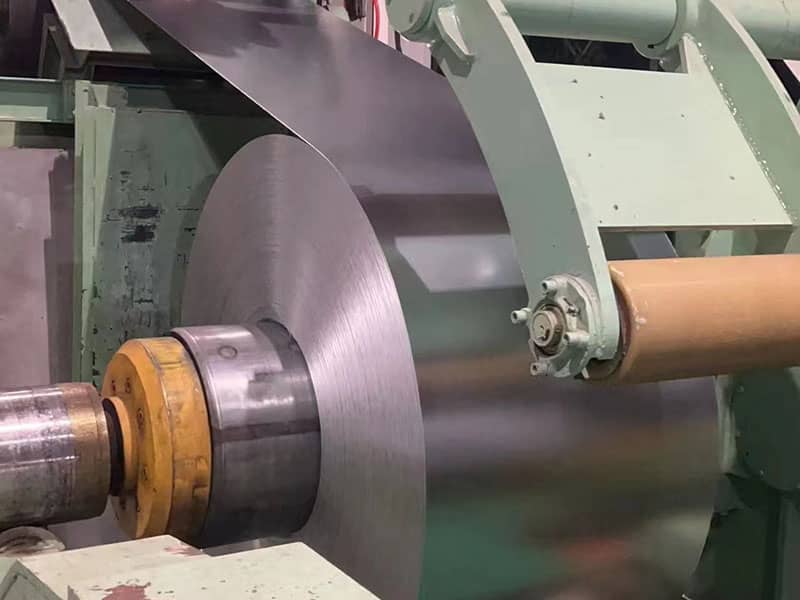

Workshops and Production Equipment

010203040506070809