01

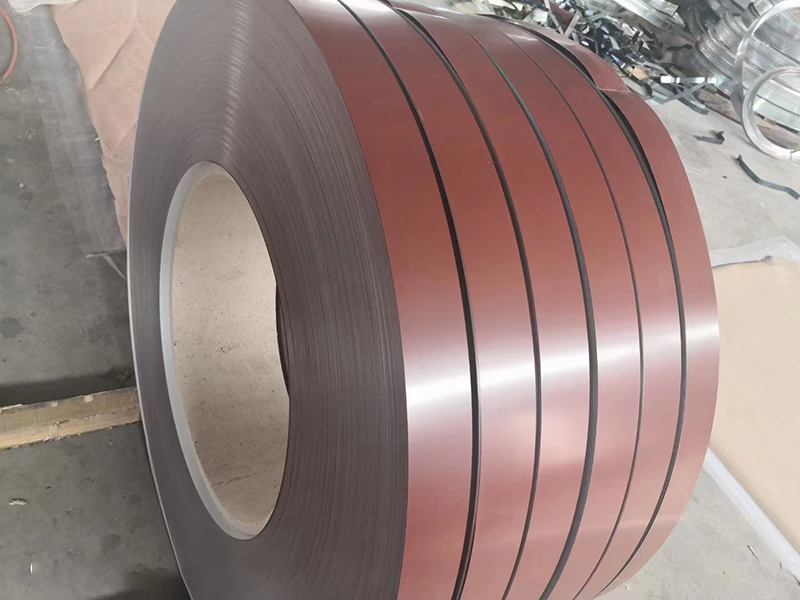

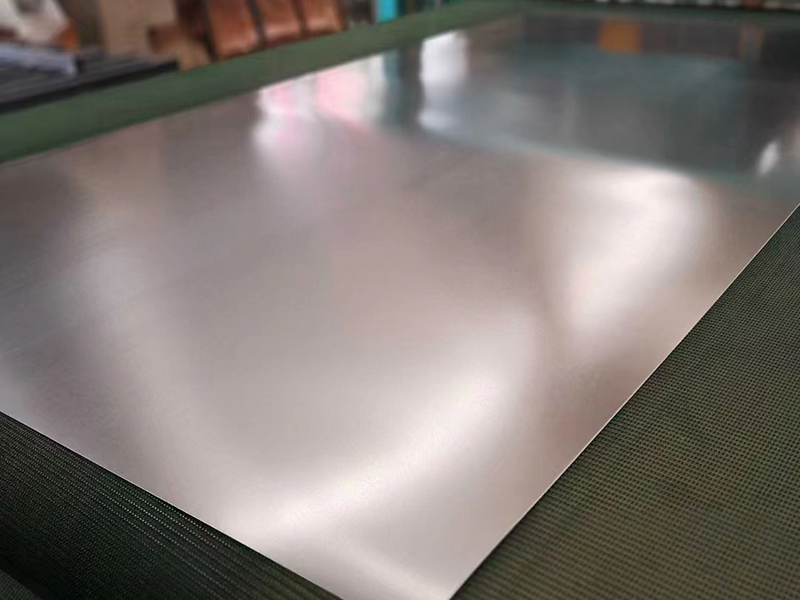

Zinc Aluminium Magnesium Steel Coils-Strips-Plates

Introductions

The application of Magnesium in immersion plating which could trace back to 1960s with the main purpose of further improving corrosion resistance for high dipped steel plates. American Inland Steel Company which was first developed Zinc,Aluminum and Magnesium ternary alloy coating and applied for the U. S. Patent. The commercialization of Zinc, Aluminum and Magnesium coatings which began in Japan in 1990s. After entering 21st century, major steel mills in Europe, South Korea, Japan and Australia have launched their zinc-Aluminum-Magnesium coating products with the differentiation and subdivision for coating compositions and product features.

S350 GD Is the European standard "EN10346-2009 continuous hot dip plated steel plate products" in the standard brand, is galvanized steel plate.The tensile strength of structural steel is greater than 350MPa, D is the meaning of galvanized plate, which is the structural galvanized plate with yield strength is greater than 350MPa. Generally speaking, the thickness of double-sided galvanized layer is 150g /㎡ or as required from party A.

DX 51 D + AZ implementation standards include national standard GB/T14978, European standard EN10346, etc., for ordinary hot plated aluminum zinc, the tensile strength coefficient of 270-500MPa, the brand does not specify the coating thickness requirements.,which gradually applied in the field of Photovoltaic.

Performances and Advantageous

Environmental Protection

Through a number of international environmental tests, which approve that it is non-toxic and harmless, stable and durable for the material; It can reduce environmental pollution by canceling the hot dip zinc production process ,It is more compliance with National requirements for green and environmental protection.

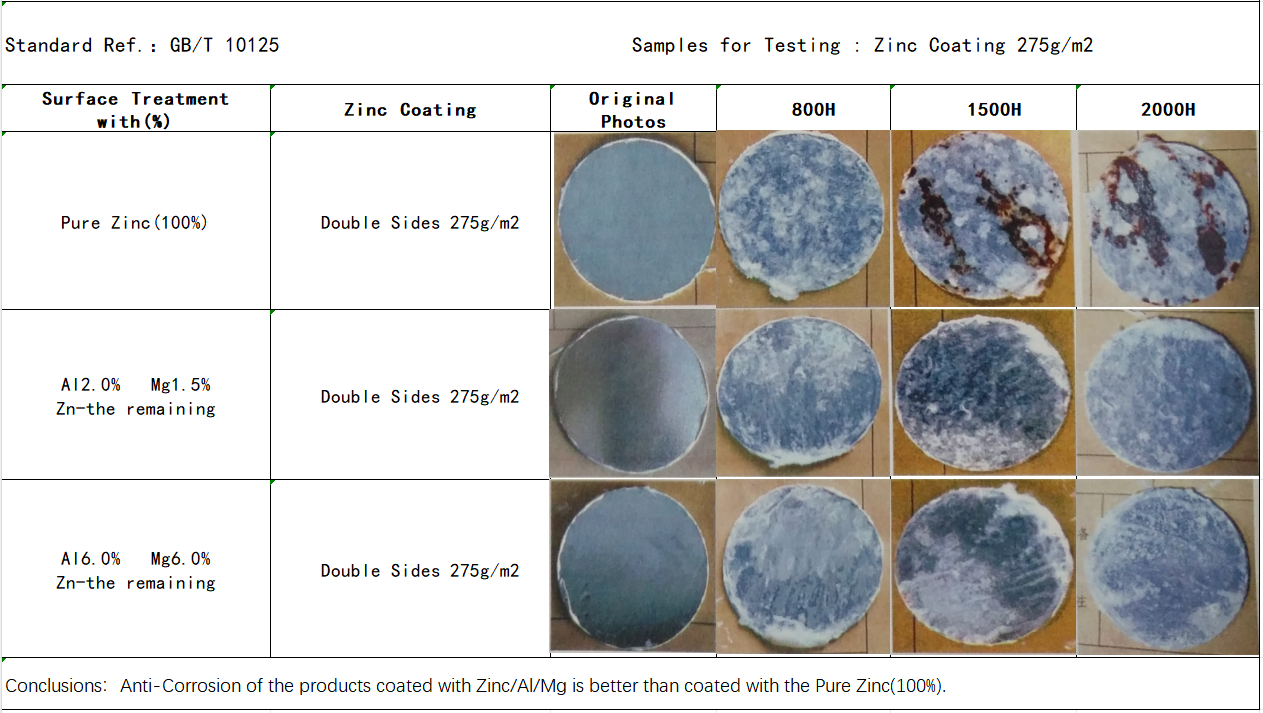

Hyper Corrosion Resistance

It is better corrosion resistance for Zinc-Al-Mg coating . It can increase the corrosion resistance of zinc-Al-mg coating steel plate up to several times or even ten times than Zinc Coating Steel plate by increasing Aluminum and Magnesium contents within a certain range.

Self-Healin

Under the conditions of humid and corrosion of the plate with Zinc-Al-Mg coating incision, coating material near the incision which constantly transfer and dye to the exposed incision through dissolution into the water film attached to the exposed metal surface , forming the dense protective film so as to prevent corrosion of the exposed incision in deeply.

Long-life

With the hyper corrosion resistance up to 10-20 times than ordinary hot galvanized sheet and the self-healing of corrosion resistance for the cutting section, it will be naturally prolonged the service life, in general, which could upto over than 30 years by use the components which be made of hot dipped galvanized-aluminum-magnesium alloy coating plate.

Processed easily

It could be used in the project in directly after forming for the plate coating with zinc-aluminum-magnesium , which can shorten processing period of components and control the project duration;The steel plate coating with hot dipped galvanized-aluminum-magnesium is more compact than galvanized steel plate, so it is not easy to peel off the coating in the process of stamping. It has excellent tensile,stamping,bending ,welding and other processing performance under severe conditions and excellent damage resistance for its higher coating hardness .

Economical

Which could decrease the cost lower 10%-20% than the ordinary hot dipped galvanized plate in meet with the requirement from properties of project.

Applications

Zn-Al-Mg alloy-coating are composed of Zn-2.0% Al-1.5%Mg. The products can be used in construction, household appliances and automotive industries.

Comparison for Results of Salt Spray Testing

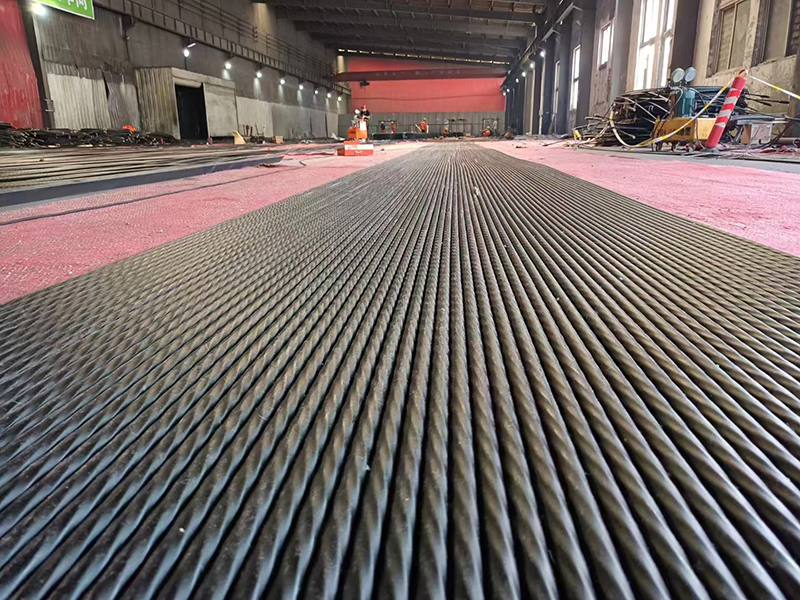

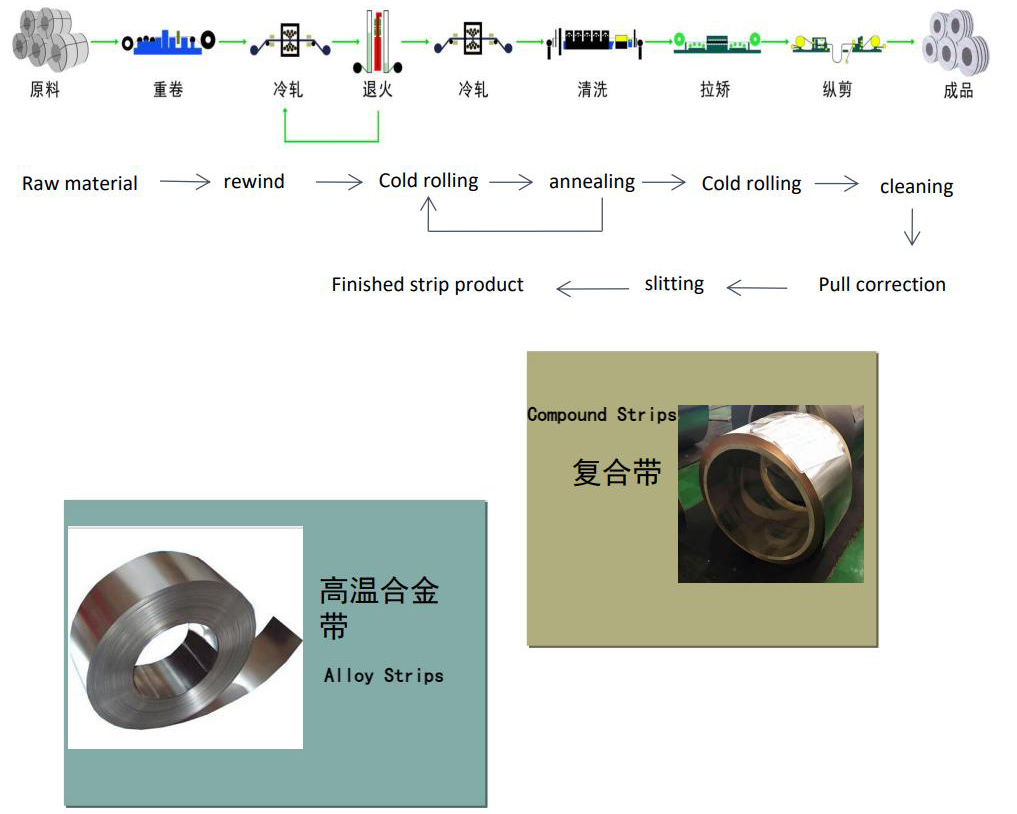

The Process Flow of Cold-Rolled coils

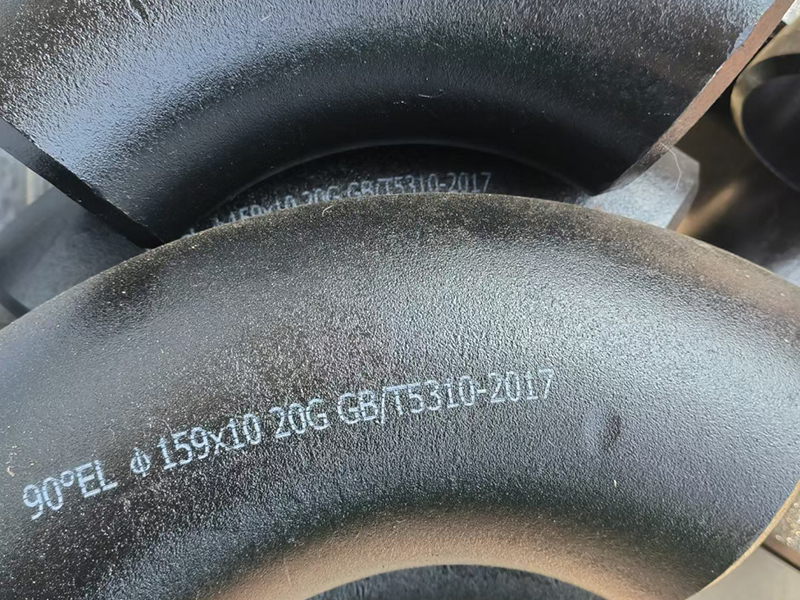

Workshops and Production Equipment

010203040506070809